Flow Temperature

Okay, this is a key point to understand throughout the whole of this article:

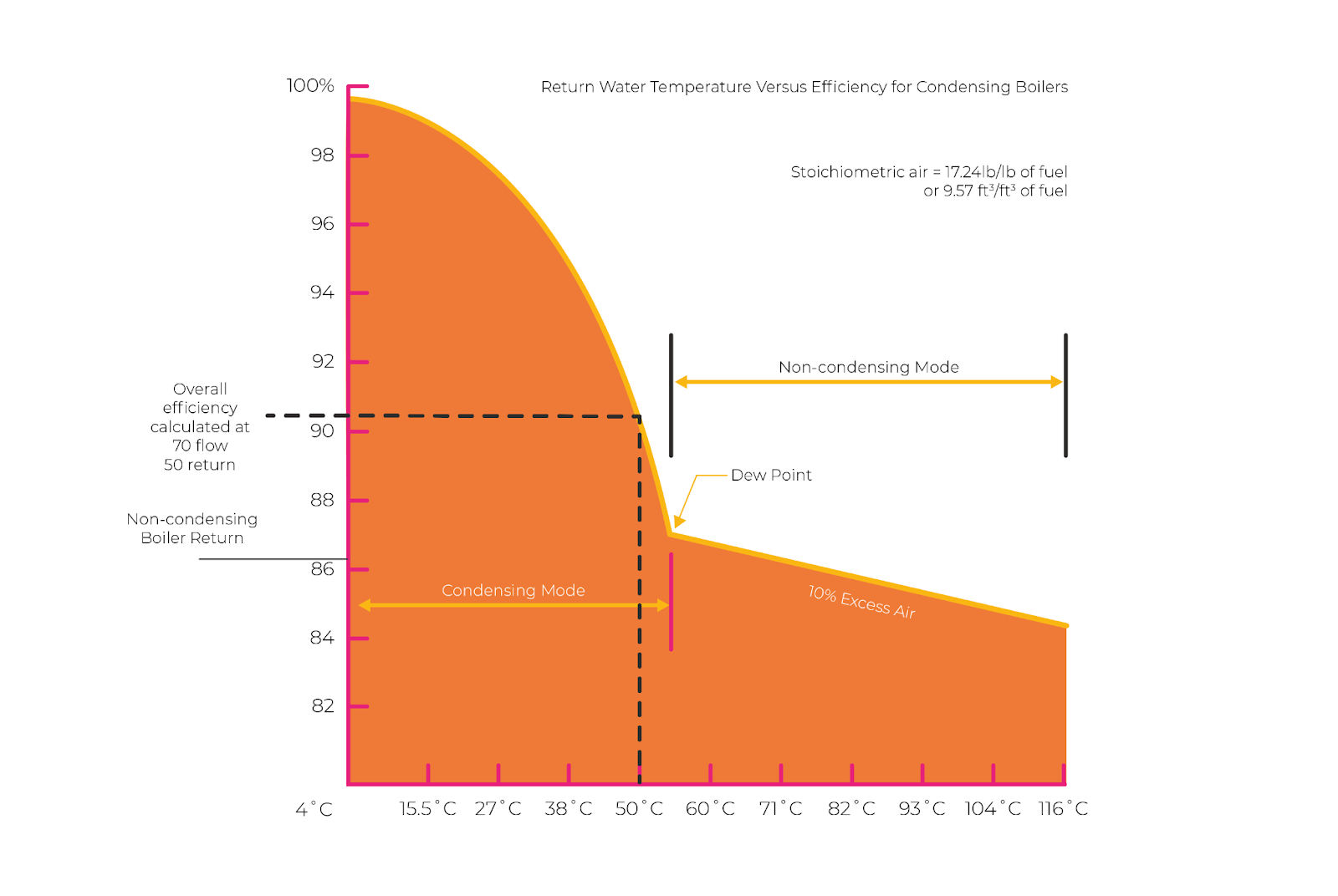

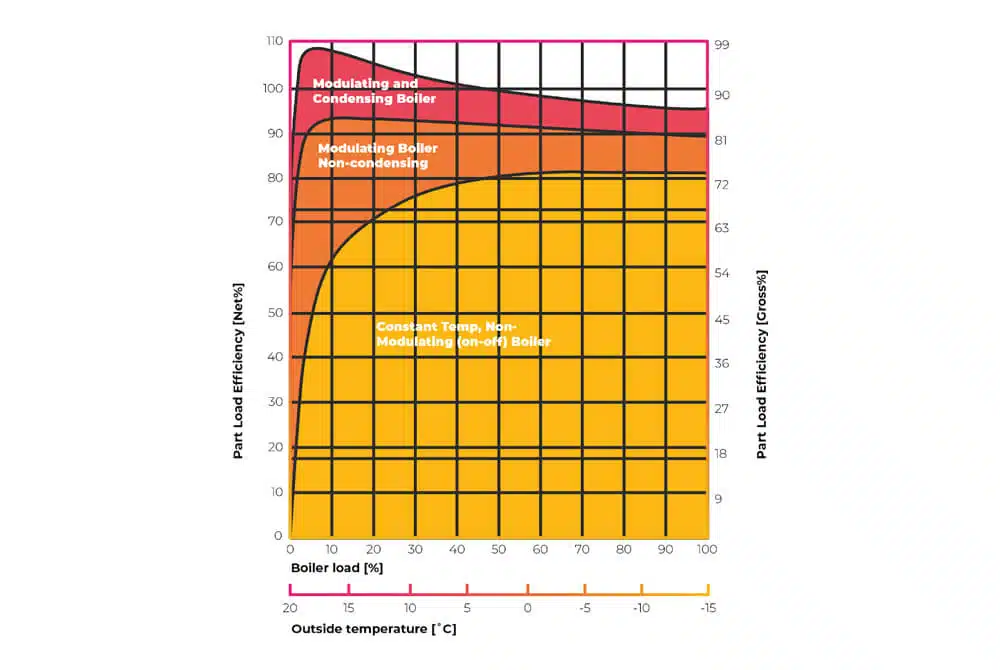

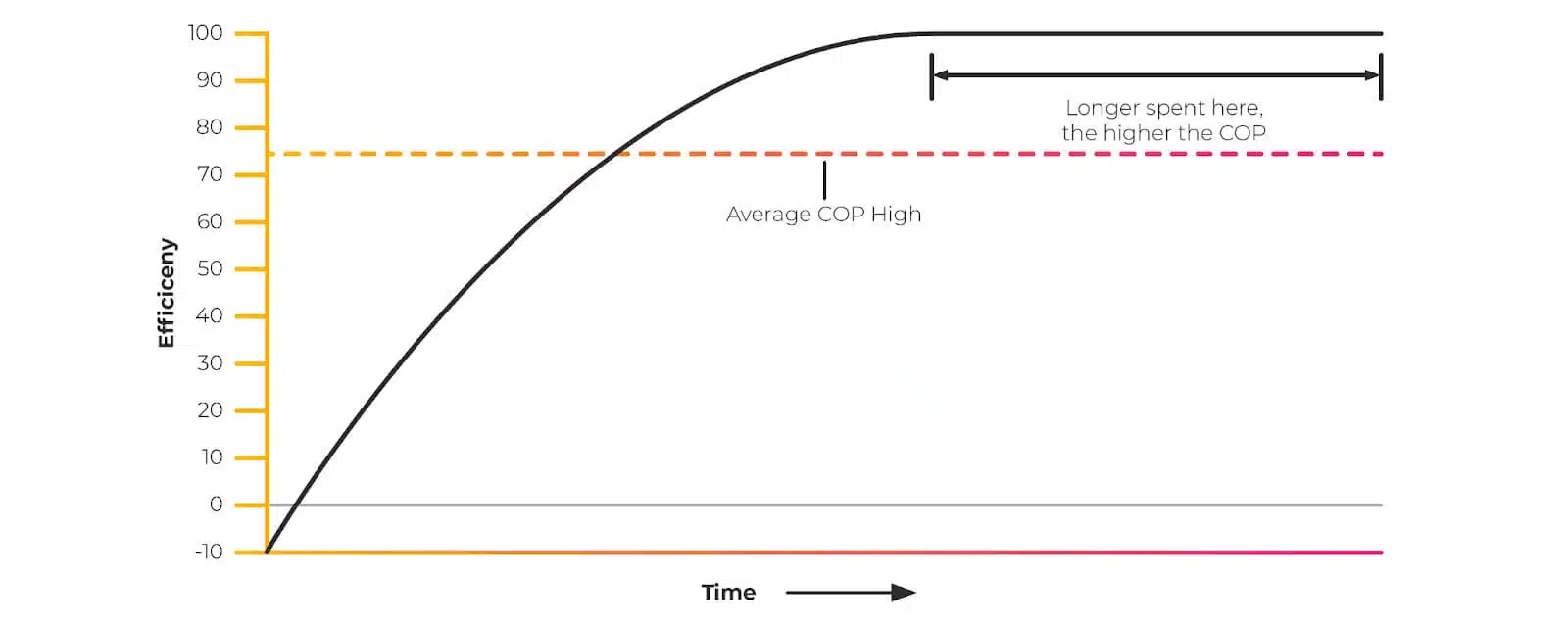

The lower the flow temperature inside your heat source, heat pump, or gas boiler, the more efficient it is.

We want to target as low a temperature as possible. By maximising the surface area of our emitters, we minimise our flow temperature.

Closing down radiators effectively reduces the surface area available to emit heat. The remaining radiators that are still on will have to run much hotter to compensate for the colder rooms next door. Here's an example we can work out together.

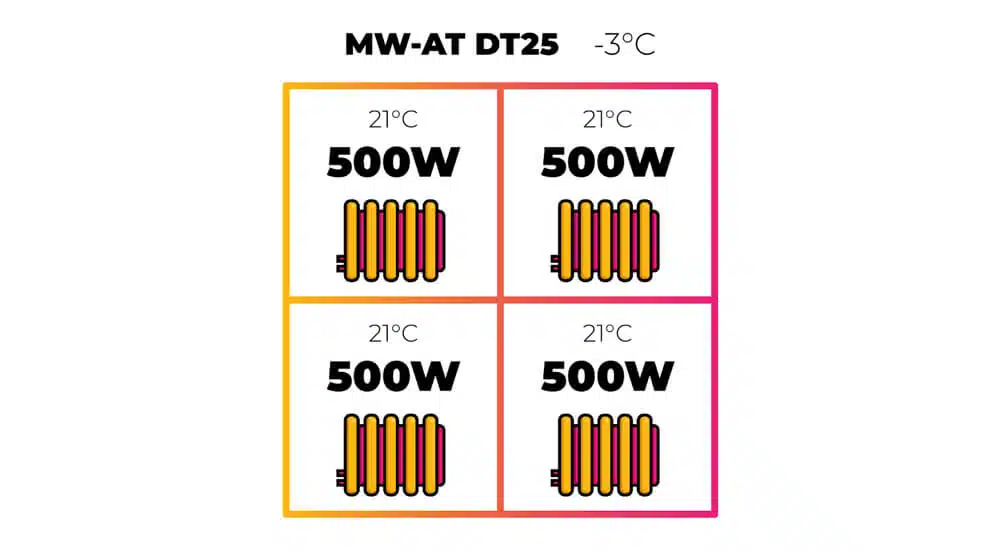

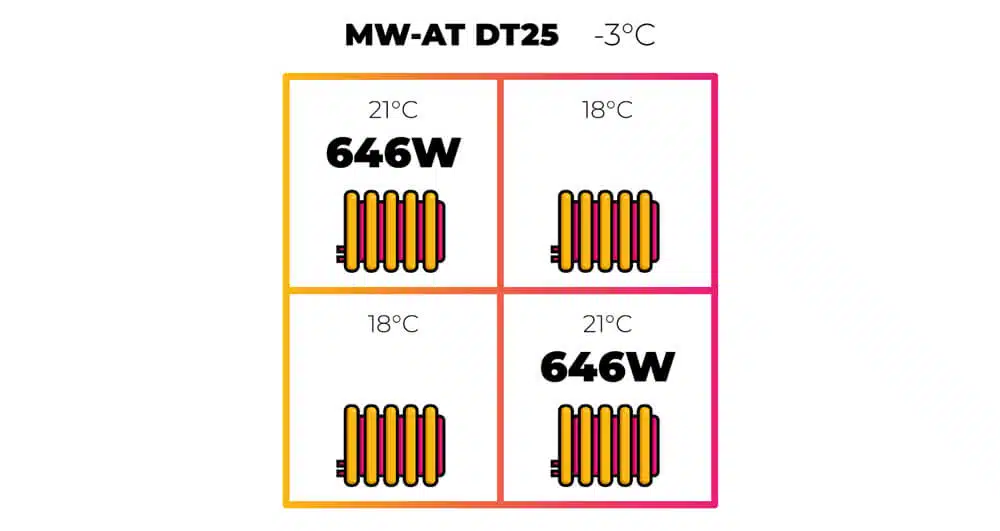

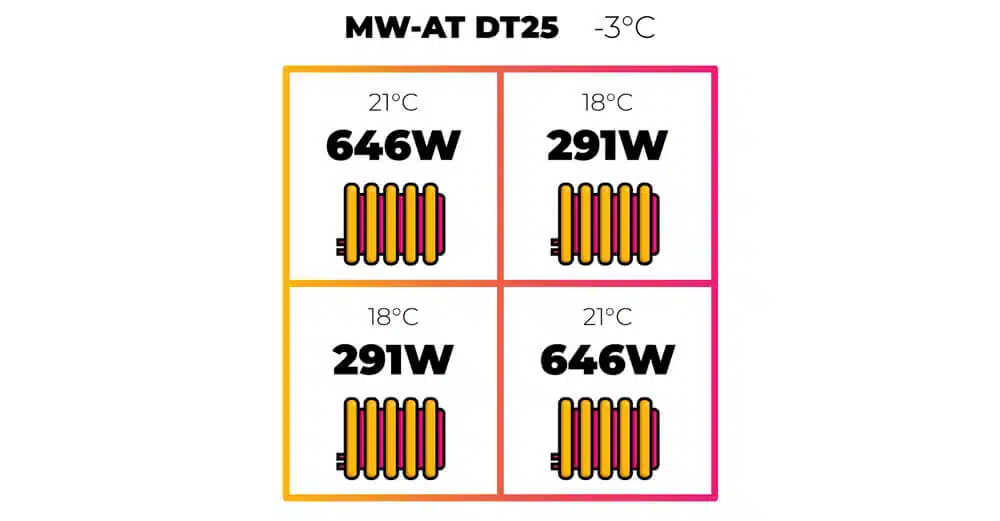

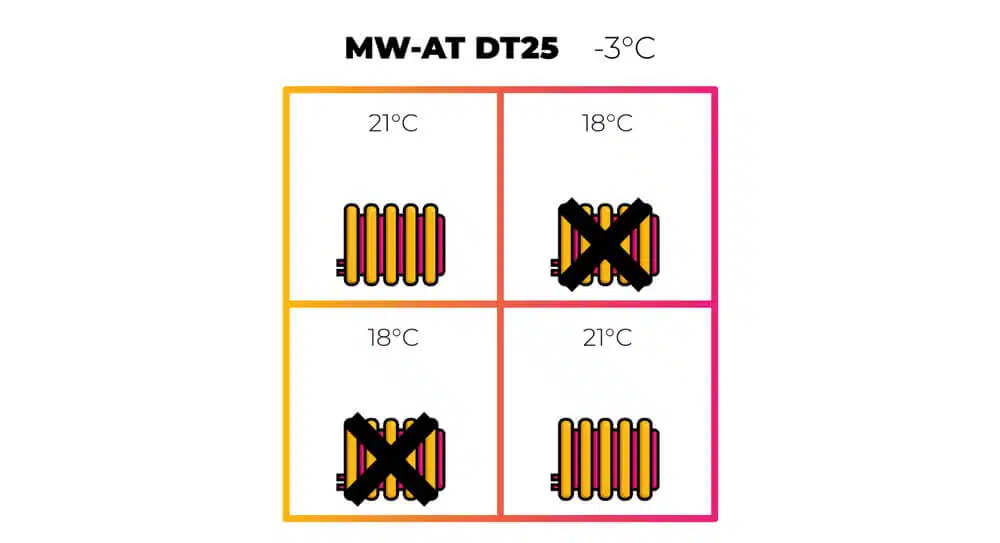

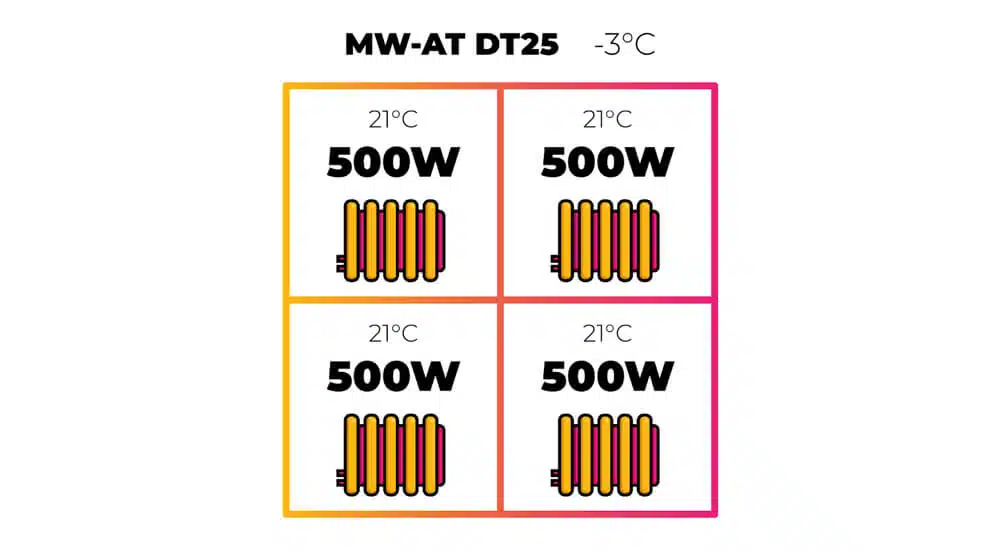

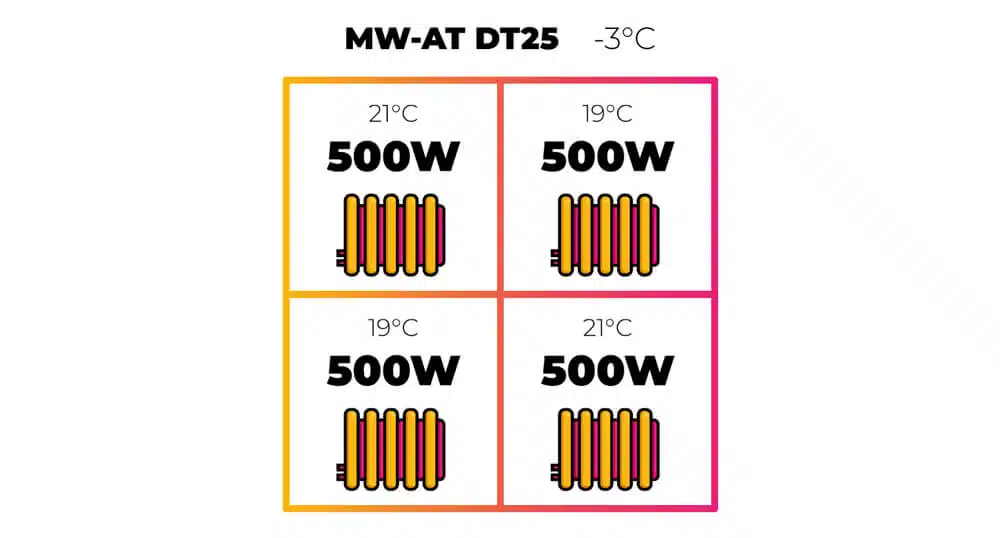

Let's take this four-room house. To keep the maths simple, each room has a 500 W heat loss at design outside temperature of −3 °C — or 2 kW in total — with a room temperature of 21 °C. Each room is fitted with a mean water-to-air temperature (ΔT 25) radiator, meaning each radiator will output 500 W when its average surface temperature is 25 °C above the room temperature.

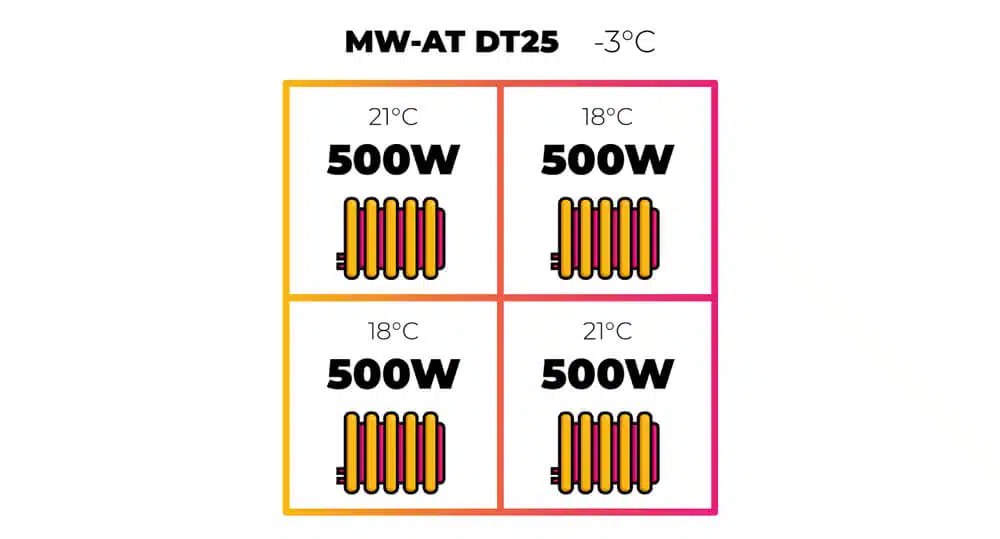

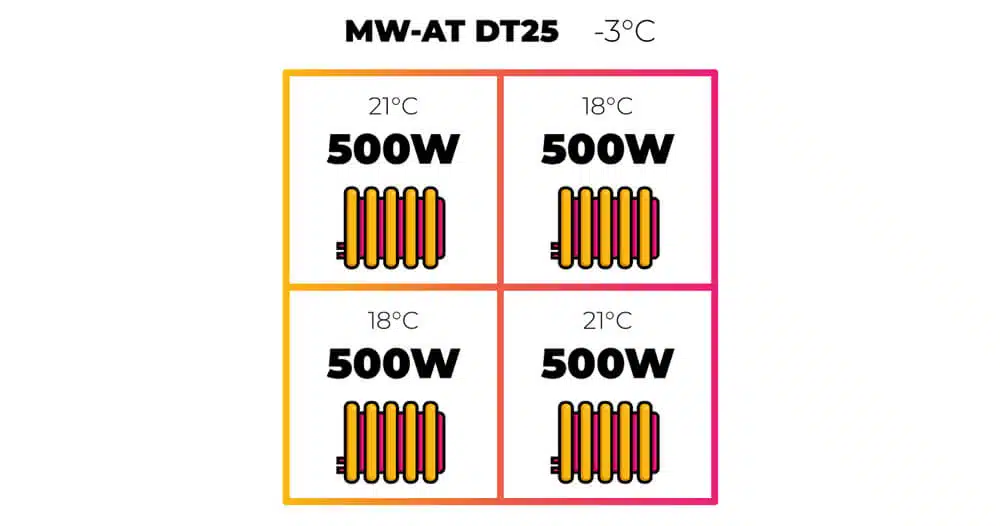

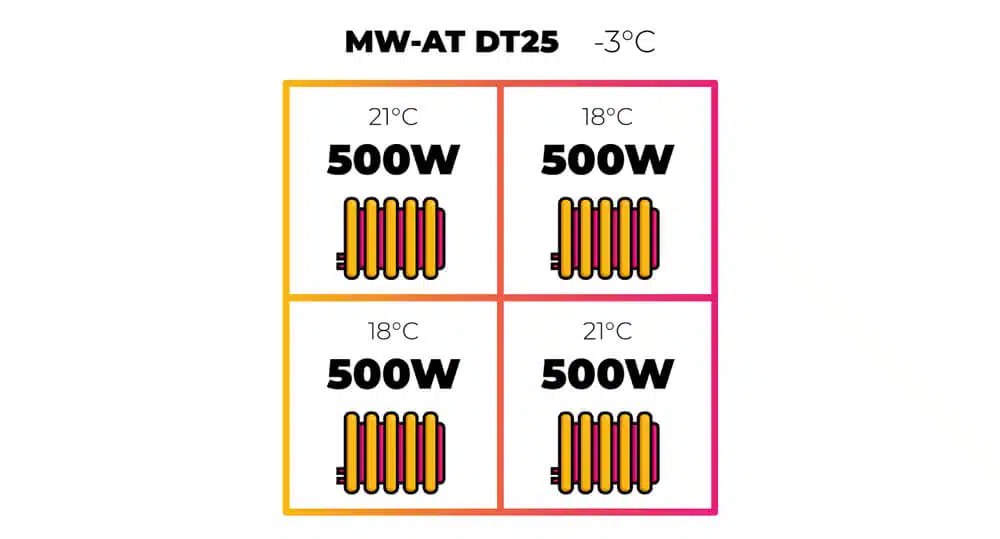

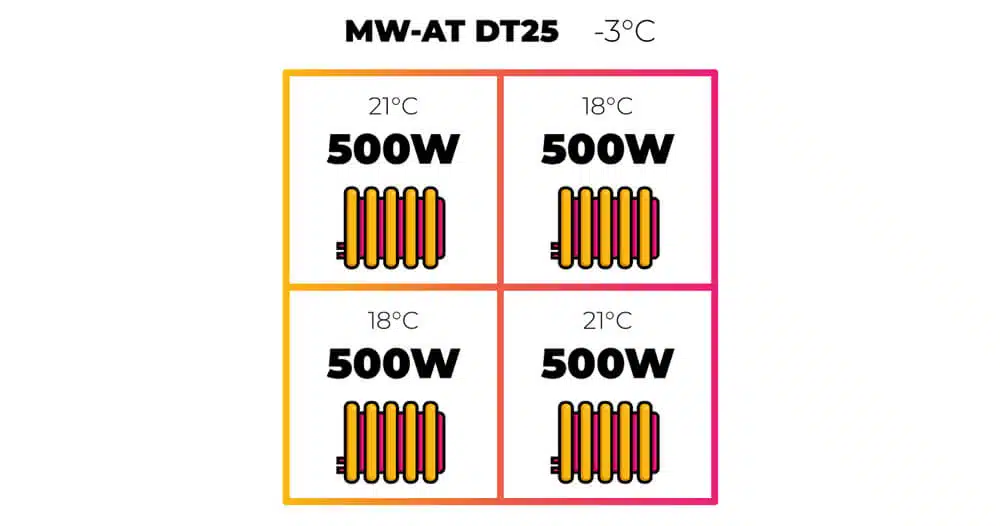

Now, let’s say you don't use two rooms, so you put them into a setback temperature of 18 °C to save energy.

A quick way to see how much heat loss this saves is by working out how much power the property takes to heat by 1 K (at design temperature) multiplied by our new average property temperature.

The property originally had a heat loss of 2 kW with ΔT 24 K:

500 × 4 = 2000 W (2 kW heat loss at ΔT 24)

This means it will require 83.3 watts per kelvin (2000 ÷ 24 = 83.3 W/K).

The new average temperature of the building is 19.5 °C, which would make our new ΔT 22.5 K:

(21 + 21 + 18 + 18) ÷ 4 = 19.5 °C (19.5 − (−3) = ΔT 22.5)

Multiply these together and you’ll see that the new load would theoretically be 1874 W if all rooms had similar heat loss.

22.5 × 83.3 = 1874 W

That’s 6.3 % less energy loss.

Heat Loss

This could be looking from above or a side view; it doesn't really matter. Turning down our radiators in the unused rooms to 18 °C in this specific scenario has saved 6 % heat loss from the property, which sounds great — or does it?

Remember, that's only if your other rooms actually drop to 18 °C, while the others remain at 21 °C. This is quite possible if you have solid, uninsulated external walls. But for any building with cavity walls or cavity insulation, even if your internal doors are permanently shut, it’s unlikely that the temperature difference will hold. Internal doors and walls are rarely fully insulated or sealed.

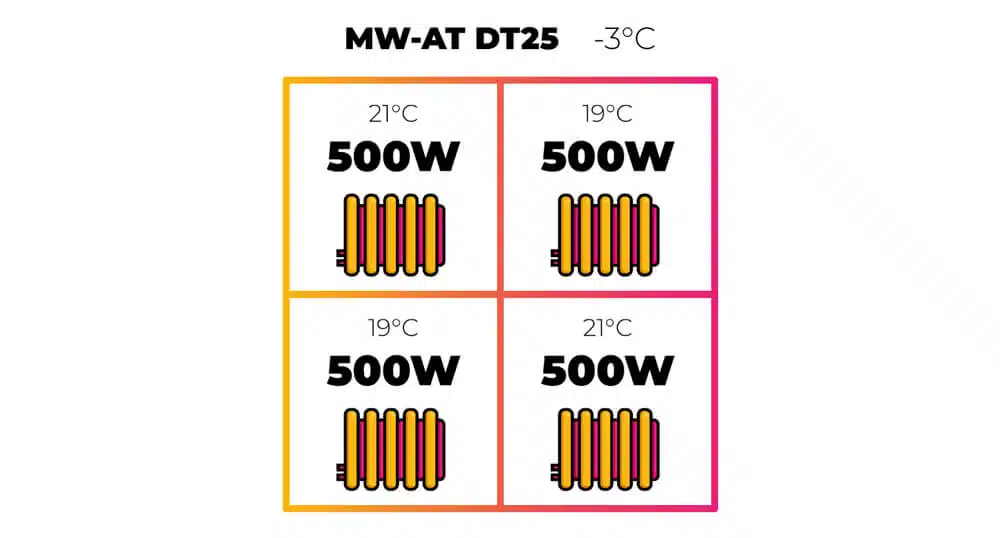

Let's say those rooms with a setback temperature of 18 °C only drop to 19 °C. Let’s work out the total heat loss from that building.

If we add all our room temperatures together and divide by 4, this gives us a mean temperature of 20 °C:

(21 + 21 + 19 + 19) ÷ 4 = 20 °C (20 − (−3) = ΔT 23)

If the building has a heat loss of 83.3 W/K, multiply this by ΔT 23 to give 1916 W heat loss.

23 × 83.3 = 1916 W

That’s a 4.2 % less energy loss.

So we’ve saved 4.2 % power or energy. But because heat is still lost into those cooler rooms, your total heat loss isn’t as low as you might expect from turning down those TRVs.

Yes, your radiators in those rooms aren't on, but the other remaining radiators are having to work much harder to heat their rooms, so the result is that you could actually only be saving 4 %.

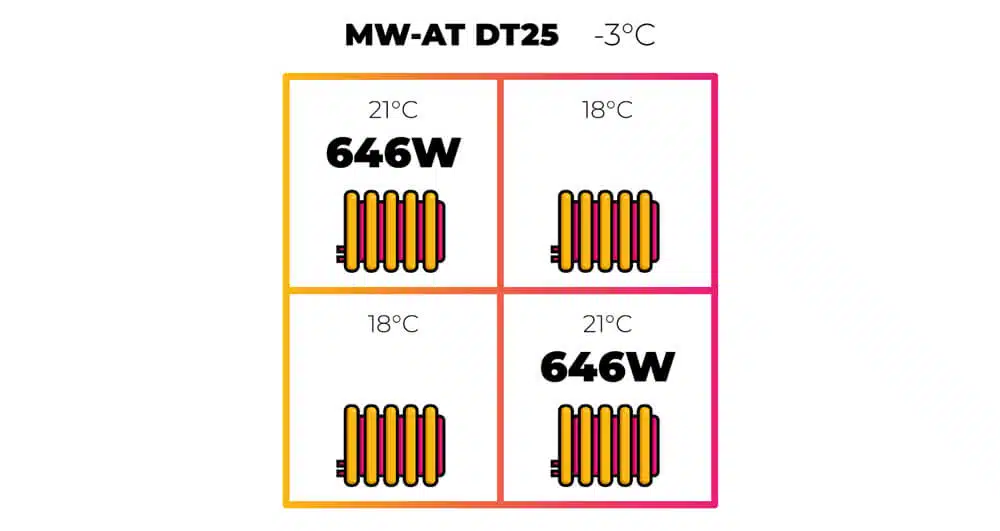

Now remember, the property was fitted with ΔT 25 radiators, meaning they output 500 W when their average surface temperature is 25 °C above the room temperature. What temperature do you think these same radiators would have to be if the adjoining rooms were 18 °C?

Let's say each internal wall is 2.3 m by 4 m and each room has a 2 m² door.

Internal Wall Area: 2.3 × 4 with a U-value of 2 W/m²K

Internal Door Area: 2 m² with a U-value of 8 W/m²K

We first work out the heat loss into adjoining rooms. 2.3 × 8 (for both walls) = 18.4 m².

2.3 × 8 = 18.4 m²

Subtract 2 m² for the door → 16.4 m². Multiply by U = 2 W/m²K → 32.8 W/K. Multiply by 3 K difference → 98.4 W heat loss through walls.

32.8 × 3 = 98.4 W

Now add the door: 2 m² × 8 W/m²K = 16 W/K. Multiply by 3 K = 48 W through the door.

16 × 3 = 48 W

Total = 98.4 + 48 = 146.4 W heat loss from each 21 °C room into the cooler rooms.

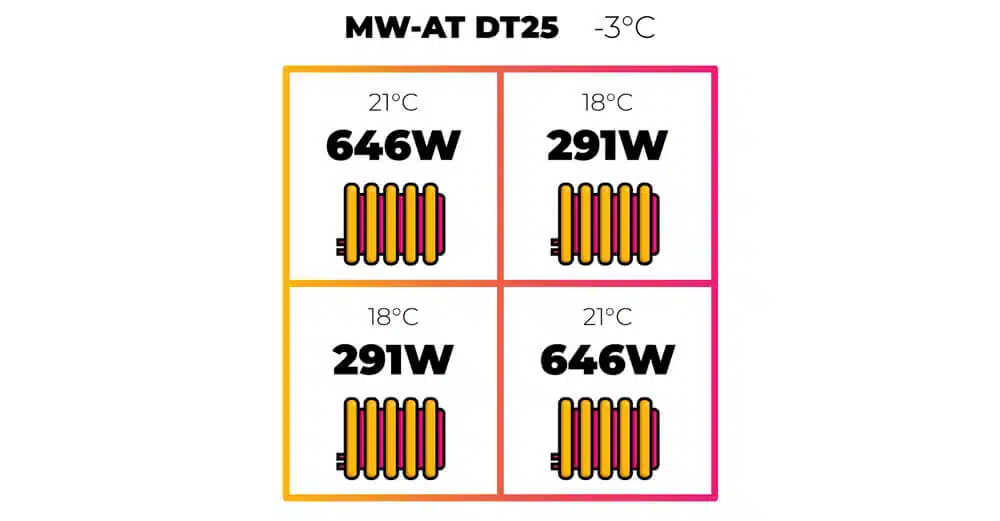

So the ΔT 25 radiator, which produces 500 W, now has to output 646.4 W (500 + 146.4).

If you remember, the property required 1874 W total. If these two radiators are outputting 1292 W, the remaining 582 W will be emitted into the two cooler rooms by their respective radiators, whose TRVs may be almost closed or pulsing heat on and off.

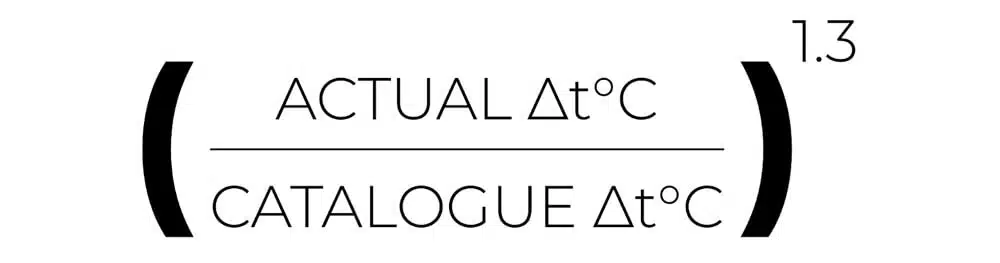

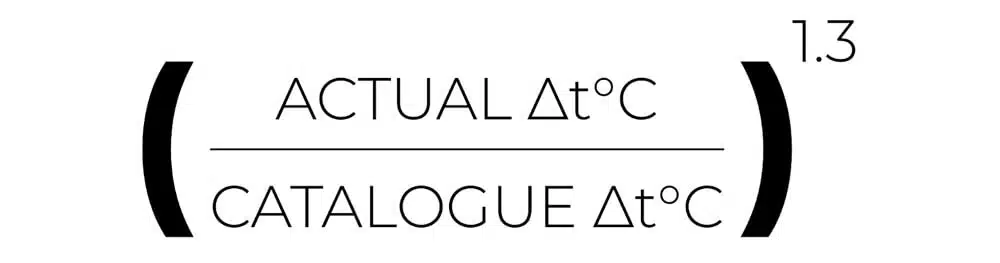

To calculate the temperature required to make a 500 W (ΔT 25) radiator output 646 W, rearrange our radiator conversion factor using the previous principles from the course.

First, determine the increase: 646 ÷ 500 = 1.292 → a 29.2 % more power required from the radiator.

We now have to account for the non-linear relationship between MW-AT and the heat output of radiators, which you might remember features an exponent of 1.3,. However, we're working the other way around here. So rather than going from ∆T difference to the power increase, we're going from the power increase to the ∆T. So we'll have to use the reciprocal of 1.3.

Remember to find the reciprocal, we divide the number 1 by the number we want to find the reciprocal of: 1 divided by 1.3 is 0.77.

1 ÷ 1.3 = 0.77

We take our 1.292 power increase to the power of 0.77, which gives 1.22 rounded up.

1.292^0.77 = 1.22

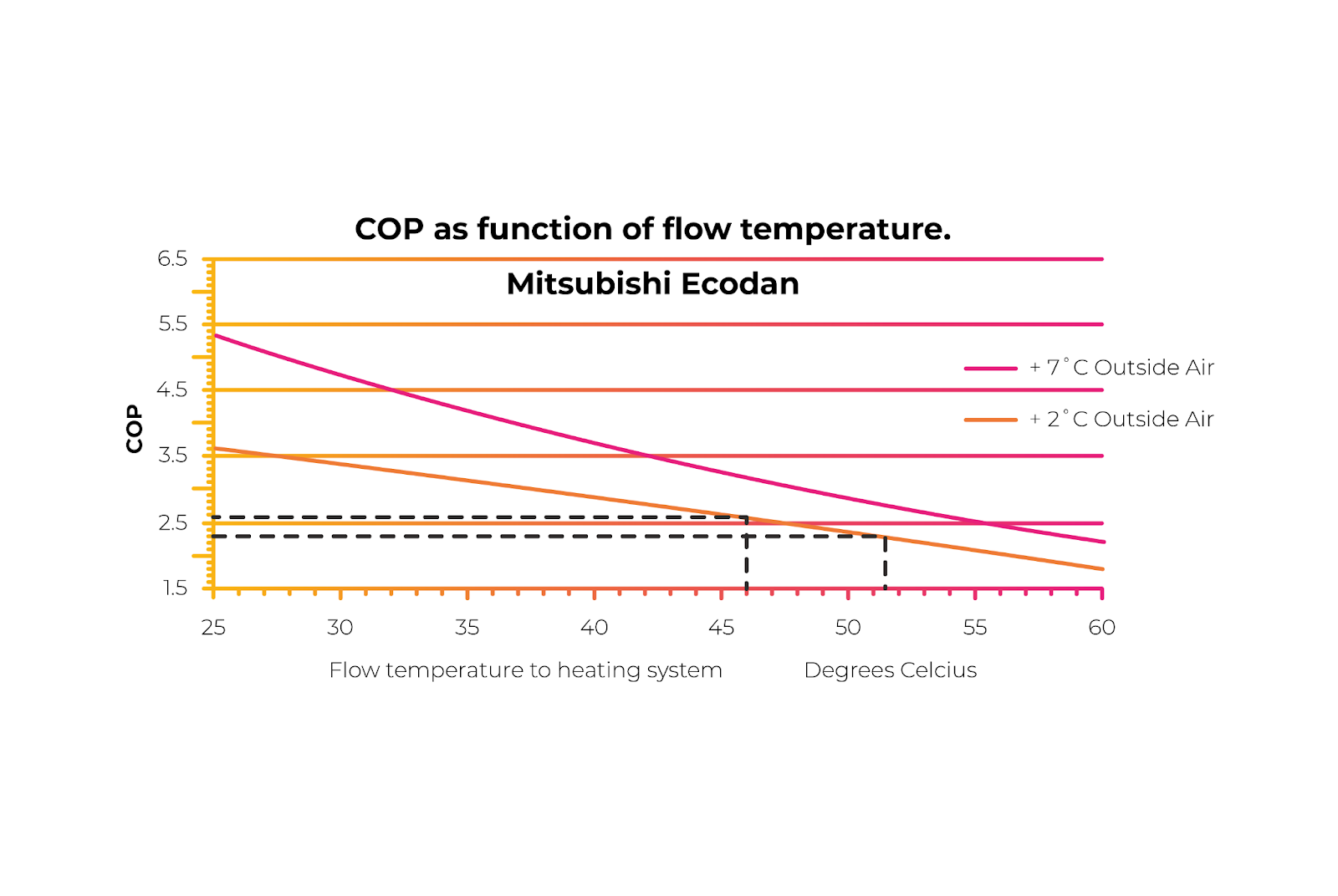

Your radiator’s mean water-to-air temperature will have to be 1.22. That's 22% hotter to output 614 W. So if the mean water-to-air temperature ∆T was previously 25°C, the new mean water-to-air temperature will have to be 30.5°C.

25 K x 1.22 = 30.5°C

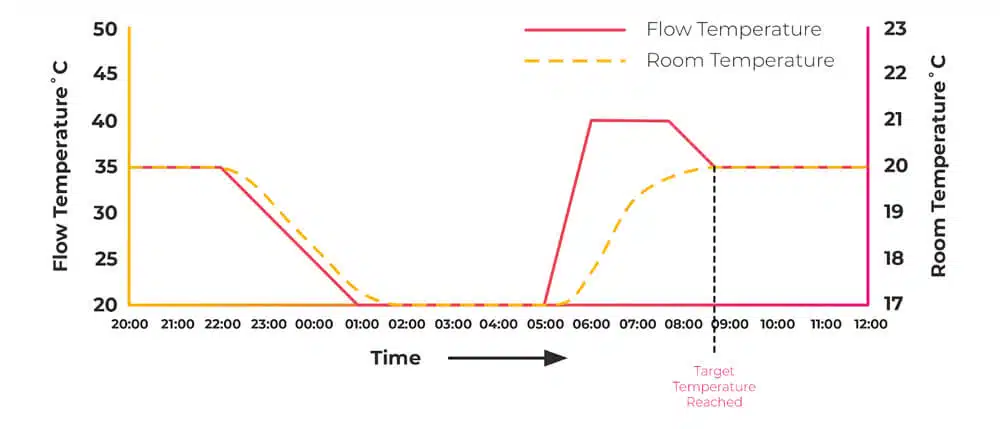

Now, with a 21°C room temperature, our mean water temperature would have been 46°C at the design outside temperature. However, it will now need 51.5 degrees celsius.

Old mean water temperature = 46°C (21°C room temp + ∆T 25)